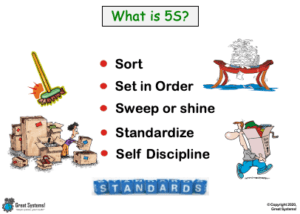

How can your work team leaders learn how to apply 5S and other lean tools?

How to Apply 5S Lean Tools

This page explores how to apply 5S lean tools in a simple, proven, and results-driven way to drive operational excellence. Organizations can gain many benefits when they install a 5S process. However, many organizations don’t know how to apply 5S lean tools in an effective way. A 5S implementation effort can be a challenge. Every staff member’s job changes if the process is truly effective.

These ten suggestions will help you avoid the 5S install failures that others suffer. I wish you the best as you attempt to keep your workplace more swept, straightened, sorted, standardized, and self-disciplined.

Don’t See Your 5S Implementation as a Stand-Alone Effort

Don’t treat your 5S initiative as a stand-alone process. Doing so can create a lot of confusion about the sudden need for such change. Besides, why bring up ‘program of the month’ memories from the past? Use of a stand-alone approach will also result in the inefficient use of resources. Instead, build regular 5S tasks and responsibilities into each team member’s daily job. Teach every team member how to apply 5S lean tools.

Many companies use special training, audits, and meetings with a specific 5S focus when they attempt to kick off a 5S initiative. Instead, build 5S practices and expectations into your larger performance improvement plan and operational excellence strategies. Similarly, don’t form a new team with a specific 5S focus and make them the 5S monitors. As an alternative, integrate 5S initiative reviews into your regular Leadership Team and work team meetings as a regular agenda item.

Require Management to Set a Strong 5S Example

Nothing kills a 5S implementation quicker than when employees walk by messy managers’ desks or work areas right after they leave a 5S project update meeting. The Leadership Team should be the most effective team in any given company. Each manager’s work area in a 5S company should be among the most clean and best organized.

Additionally, you should expect every member of management to reinforce 5S practices consistently and regularly. If a manager sees someone not practicing 5S ideals, they should politely challenge those people. Ask them to correct the behavior or condition, even if that person does not report to them.

EXPLORE MORE: How to Measure and Improve Your Leadership Work System

Expect Every Leader to Know How to Apply 5S Lean Tools

The monthly walk-through (high performance workplace audit) I share below is a great tool to measure 5S progress. The use of walkthroughs helps reinforce 5S expectations. Also, recognize that supervisors conduct informal performance audits whenever they spend time with their people. What is not said often sends a stronger message than what is said.

Do your supervisors walk by someone who is violating a 5S (or other type of high performance) expectation? Do they correct the behavior? If not, this sends a message to the employee that their behavior is OK. Similarly, the daily reinforcement of good 5S practices when you see them carries much more weight than saying ‘thank you’ to the overall group in a meeting.

LEARN MORE: Does Your Team Structure Drive Operational Excellence?

Incorporate 5S Expectations into EVERY Employee’s Job Description

If you want your work areas to remain swept, straightened, and shiny, expect each employee to leave them that they when they go home for the evening. One way to accomplish this is with a re-write of EVERY job description to include 5S expectations.

Plus, leaders should regularly emphasize this expectation in work team meetings. Finally, provide immediate performance feedback when a workplace does not meet the expectation at the end of a shift or day.

Clearly, and Visually, Define What Each 5S Workplace Should Look Like

‘Before and after’ pictures of 5S implementation progress send a strong message about what is expected and will be recognized. Pictures also help people better understand what each 5S concept should look like when it is put in place on the job.

Additionally, you may benefit from tours of ‘5S best practice’ work areas. Talk with the teams in these areas about the differences between their old workplace and how their new workplace looks.

Modify Procedures and Work Instructions to Keep 5S Changes Alive

If you want everyone to adhere to the “A place for everything and everything in its place” philosophy, you had better rewrite your procedures. Include steps that describe how to put things back where they belong.

Make sure that clear, easy to use procedures exist for waste, obsolete product, or supply disposal. After all, don’t our work instructions define what others expect from us at work each day?

EXPLORE MORE: Workplace Safety Best Practices

Build 5S Expectations Into Your Monthly High Performance Work Practices Walk-Through

Sure, you can do a special 5S walk-through each month just like you do the monthly safety inspection. However, you will make a much better time investment if you include 5S expectations as part of a monthly high-performance practices walk through assessment tool.

For example, in addition to looking for consistency of 5S practices, also look for consistency in the use of other practices. Such practices include visual performance posts, safe work practices, proper changeovers, and six sigma project support. Ask questions to help gauge general staff awareness of high-performance concepts as you move through the work area.

Include 5S Recognition in Your Regular Employee Recognition Efforts

One positive thing you can do is recognize each team monthly that meets or exceeds the minimum score on the high-performance work practices walk through. Avoid the tendency to give out a “Cleanest Workplace of the Month” or a “Most Organized Department” award.

Don’t punish those groups who end up on the bottom half of the list. You only have so many recognition dollars to spend in your budget. Use them to recognize team success against a broad set of high-performance work practice criteria.

Create a 5S Implementation Punch List and Show Regular Progress Towards Its Completion

One of the best things about a 5S implementation is that once you get over the initial hump, it is relatively easy to keep 5S alive. For example, once you sort out your obsolete equipment and supplies, you should not have to do those tasks again if people fulfill the expectations of their ‘new’ daily job.

First, create a single 5S punch list for the whole facility. Focus on what needs to be done this week to help move the 5S implementation effort forward. Then, review it weekly as part of your Leadership Team meeting (don’t form a 5S Implementation Team). If you track the percent complete for each action item on the action plan, you can easily keep up with the progress of your initiative. Repeat this same process with each work team.

Create a 5S Implementation Plan with Milestones that Appreciate Process Evolution

If you follow the above nine guidelines, you should see progress in a relatively short amount of time. Additionally, you should see little regression back to where you were at the start of your 5S initiative. For example, after 3-6 weeks of consistent sweeping and straightening up at the end of each day, that behavior should become a habit. Each workplace should be much cleaner. The need to emphasize and spend time on these two pieces of the 5S puzzle should be low.

Also, you will make a big effort to get rid of the excess stuff you have collected over the years. When you do, create a more effective approach to storage for your key work areas. If you reinforce this new practice daily, you should not have to worry about doing those tasks again. The key lies in teaching each team member how to apply 5S lean tools in their daily job.

Finally, I hope you can see how other operational excellence and lean six sigma approaches can benefit from the use of several of these tips as well. For example, if you change job descriptions to include a 5S emphasis, consider the inclusion of six sigma project support and process improvement tool practice as well. In short, build high performance practices, expectations, and measurements into your larger work systems.

Keep improving!

Kevin McManus, Chief Excellence Officer, Great Systems

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

CHECK OUT my ‘Teach Your Teams’ workbooks on Amazon.com

LIKE Great Systems on Facebook

© Copyright 2024, Great Systems LLC, All Rights Reserved