Do You Have Great Work Systems?

Great work systems help sustain daily kaizen and drive OPEX (operational excellence) across key performance areas. This is easy to say. For some, it is also easy to do.

However, too many organizations struggle to install great work systems. Even a higher percentage don’t even know how ‘less than great’ (how poor) their current work systems are. In turn, they don’t see a need to improve.

Worse yet, when they do attempt to improve, they simply ask people to be more careful, work harder, and be less wasteful to make change happen. They fail to recognize that a work system gives you what you design it to give you.

Work systems with poor designs tend to consistently give you substandard results, whether you know it or not.

What is a Work System?

In his book “The New Economics”, Dr. W. Edwards Deming defines a system as “a network of interdependent components that work together to try to accomplish the aim of the system.” In his book “The Fifth Discipline”, Peter Senge, who was a disciple of Deming, adds that systems are “invisible fabrics of interrelated actions which often take years to fully play out their effects on each other.”

For example, the human body consists of many different systems. Systems, such as those of a respiratory, circulatory, and neurological nature, allow us to exist and live each day.

Freeway systems consist of on and off ramps, shoulders, traffic lanes, and signage. These traffic systems work together to help guide traffic to its destination.

Work systems exist in a similar sense. We may not be aware of their design, or of the different aims of the different work system designs in place. In many cases, we simply come to work each day and do things as they have been done by others before us.

This may even include ourselves. We don’t give much thought to why we do things this way. We fail to question why our actual results (the real aims) our different systems produce are inconsistent with the aims we desire.

How Does the Baldrige Criteria Define a Work System?

I base my own operational definition of a system on the use of the term “systematic” in the Malcolm Baldrige National Performance Excellence Award criteria. That definition refers to “approaches that are well-ordered, repeatable, and use data and information so that improvement and learning are possible.”

In most organizations, the work systems are repeatable, but leaders may not measure the results they provide. Unfortunately, the processes people repeat each day as a part of a given work system may NOT produce the types of results that they truly desire. Also, all people and work groups might NOT execute these systems in a similar manner across the organization. Finally, trends and data might not be in use to gauge process performance and identify key problems. How can the organization learn and improve?

LEARN MORE: How to Measure and Improve Your Leadership Work System

How Systematic are Your Work Systems?

For example, if we look at the patterns of behaviors leaders use to create organizational plans of different types, we can define their planning system. Different departments or leaders may use a set of processes however to arrive at their plans that is inconsistent with the ones that others in their company use. Few actually measure the effectiveness of their planning process. This makes it tough to improve this key work system over time.

They have a planning system, but that planning system is not systematic. I have unfortunately found that in most organizations, this can be also be said for the daily leadership, customer satisfaction, employee engagement, training, measurement, hiring, and other key work systems that are in use. Worst of all, because these key work processes are not well ordered or effectively measured, they are waste laden. One of the key waste streams we feed daily involves how we use the limited time each of us has to devote to our work each day.

What is the Difference Between a System and a Process?

In short, a system is a collection of processes. For example, a leadership work system consists of several processes, including a development process, an evaluation process, and an expectations definition process. A process is a series of repeatable steps – simple enough?

As we perform our personal routines each day, we execute repeatable steps in both a predictable and measurable way. We follow a lot of these steps subconsciously. Teeth brushing, showering, driving to and from work, going to meetings, processing e-mail, eating lunch (versus dinner), and managing projects are all examples of processes.

LEARN MORE: How to Measure and Improve Your Job Design Work System

All Work is a Process, and All Processes Can Be Improved

In our organizations, it is the same. All work is a process. We repeatedly execute a series of steps each day to produce a product or provide a service.

We do this as individuals. This occurs in teams when we meet, and in the decisions we make as a managers and leaders. Each of these cycles has an average cycle time and a cost. There is also a degree of somewhat measurable effectiveness in terms of customer satisfaction.

To save money, you eliminate non-value activities and reduce cycle time. You improve the activities that add value so that they provide even greater value. This is not just a work thing. It is just as applicable in our personal lives.

LISTEN TO my ‘How to be Proactive with Process Improvement’ Real Life Work podcast

What Does “A System Will Give You What It is Designed to Give You” Mean?

The structure of a given system gives you a certain mix of results, whether you are aware of these results or not. For example, weather, highway, legal, automotive, and the various systems in the human organism help determine the time you need to travel to and from work each day.

You might have a strong desire to cut your travel time to work in half. If you want to actually make this happen on a consistent basis, you have to change the systems that produce your current results.

Similarly, your existing leadership work system generates a certain mix of leadership results in your organization. You can ask or demand that your leaders become better process improvers, motivators, or coaches, but this will not happen if you don’t change the systems that you currently use to develop and evaluate your leaders.

LEARN MORE: How to Measure and Improve Your Process Improvement Work System

You might define the strategic need to hire employees who care more, are absent less, and have higher skill levels. However, this need won’t become a reality unless you change the systems you use to recruit, hire, and retain employees.

Do you have a weak hiring process? If so, you will hire substandard people, whether you have a stated goal to avoid doing so or not. If you fail to address employee needs or fairly compensate them, you will fail to retain your good people, whether you like it or not.

How are Great Work Systems and Culture Change Related?

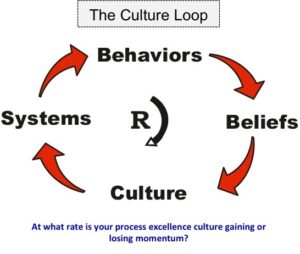

In my 2006 book “You Can’t Win Indy in an Edsel – How To Develop a High Performance Work Culture”, I make a simple statement. Change systems to shift cultures.

Organizational cultures develop over time. First, your existing work culture is shaped by the people your hiring process brings into the organization. Second, your work systems help reinforce daily work behaviors and beliefs.

You can’t simply ask, let alone order, people to change and shift a culture towards continuous improvement. You have change the systems that you use to measure performance.

People need to be taught new skills. Leaders must consistently reinforce performance expectations.

From forty years of work experience and 20-plus years of national Baldrige Examiner experience, I have been able to define ten key work systems that high performance organizations rely on. These work systems help drive consistent improvement in the results their work processes deliver over time.

EXPLORE MORE: Ten Ways to Change a Work Culture

How Do I Know If I Have Great Work Systems?

Measure and trend the performance of your work systems over time to begin your systems assessment. Without measures, and trends for those measures, you can’t begin to assess systems greatness.

Plus, you must measure the right mix of things. Don’t just measure certain aspects of a system’s performance. For example, some supervisors only measure throughput, even though processes also generate quality, cost, safety, and people results.

LEARN MORE: How to Measure and Improve Your Measurement Work System

Effective work systems demonstrate consistent improvement over time, in all areas of importance. The mix of performance areas that exist (such as safety, quality, people, cost, and revenue generation) help define areas of importance.

Also, importance areas include those departments, product types, and locations that produce results. How great are your work systems?

After you assess the degree that your work systems consistently improve over time in all areas of importance, you are in a position to assess true greatness. Compare the performance of your systems to others in your sector and outside of your work.

The truly great organizations have work systems that produce results which are not only better than others in their line of work produce, but are also better than those in other lines of work produce. They are true role models.

How Can I Build Great Work Systems?

In order to build great work systems, you have to improve the processes that are part of each system. You also must improve the manner in which these processes interface with each other.

To improve a process, you have to reduce process waste. This is the focus of most lean six sigma initiatives. Unfortunately, such improvement efforts contain two critical errors.

First of all, they fail to perform effective root cause analysis. Most commonly, we tend to assume that human error is the root cause. We don’t look for the systemic causes of repeat human error.

Second, we write poor, and largely ineffective, corrective actions. We might not actually address the systemic root causes of a problem. In turn, we waste a lot of time and money.

Frustration creeps into our work teams. Our problems continue to haunt us. We fail to make the transition from reactive work to proactive work.

DISCOVER MORE: Evaluating Root Cause Analysis Processes

Improve Each Process to Create Great Work Systems

To improve each process, minimize process waste and increase the level of customer value that the process delivers. Additionally, look at how one process depends on the results from other processes. Plus, ask how the process helps determine the results of other processes.

Too many organizations focus only on cost or waste reduction. They fail to also try to increase customer value. They fail to work with their internal or external customers to determine what types of process results are needed or are currently being obtained. For example, most organizations that pursue lean and six sigma initiatives only engage 10-15% of their employees in these efforts.

If you want different results, you have to change the systems that produce the results you do not like. That’s the theory, but how do you make this happen?

Fortunately, you don’t have to blaze new trails by yourself. There is a small percentage of organizations that already have great work systems in place. I estimate this number at 5-10%. If you study these systems, you can redesign your own work systems to better mirror them and sustain better results.

LEARN MORE: How to Measure and Improve Your Training and Learning Work System

Keep improving!

Kevin McManus, Chief Excellence Officer, Great Systems

WATCH over 50 kaizen and workplace health improvement videos on my Great Systems YouTube channel.

CHECK OUT my ‘Teach Your Teams’ workbooks on Amazon.com

LIKE Great Systems on Facebook

© Copyright 2024, Great Systems LLC, All Rights Reserved